- Home

- Products

- Fire damper cartridges

- SCV+90

- Installation

SCV+90 - Installation

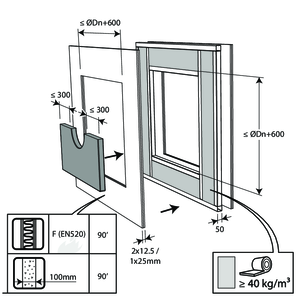

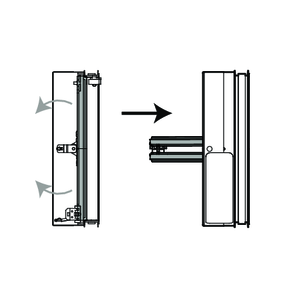

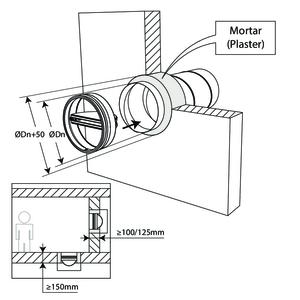

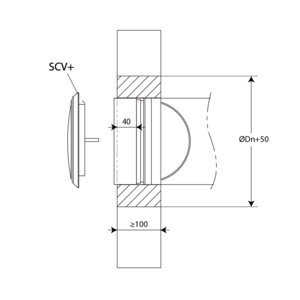

Installation in rigid wall and floor, sealing mortar

The product was tested and approved in:

- Aerated concrete ≥ 100 mm | EI 90 (ve i o) S - (300Pa) | Mortar | Type of installation: built-in inside a duct, 0-360° | SCV+90 Ø 100-200 mm

- Aerated concrete ≥ 150 mm | EI 90 (ho i o) S - (300Pa) | Mortar | Type of installation: built-in inside a duct, 0-360° | SC(V)+90

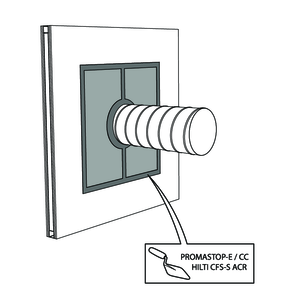

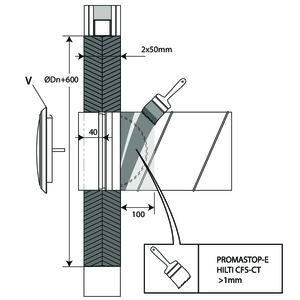

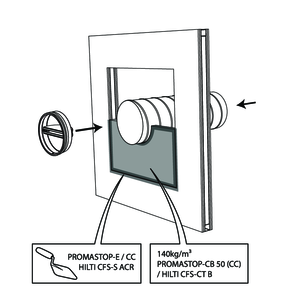

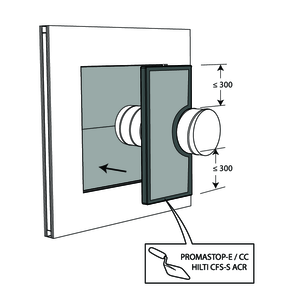

Installation in flexible and rigid wall, sealing with rigid stone wool boards with coating - SC(V)+90

The product was tested and approved in:

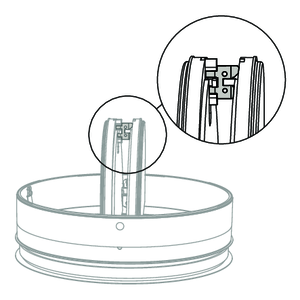

The opening in the wall around the duct in which the fire damper cartridge is mounted, is sealed with 2 layers of 50 mm-thick stone wool panels with fire resistant coating on one side (type PROMASTOP-CB 50 / PROMASTOP-CB/CC 50 / HILTI CFS-CT B).

The joints on these 2 layers must be installed staggered and covered all around the edge with coating (type PROMASTOP-CC / HILTI CFS-S-ACR / Mulcol Multimastic SP).

General remarks

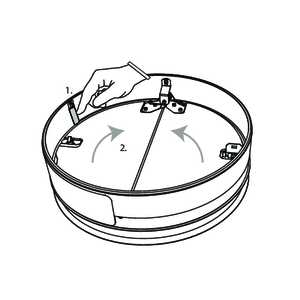

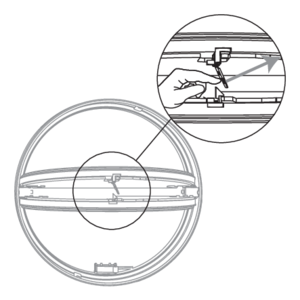

- Verify if the blade can move freely.

- The fire damper cartridge must remain accessible for inspection and maintenance.

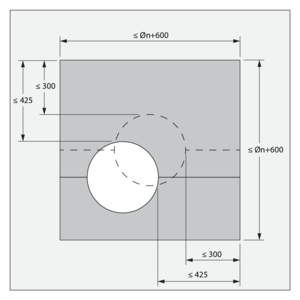

- Please observe safety distances with respect to other construction elements.

Product-specific remarks

- The installation must comply with the installation manual and the classification report.

- The results obtained in standardised supporting structures according to EN 1366-2 also apply to similar supporting structures with a fire resistance, thickness and density equal to or greater than the supporting structure of the test. More information on standardised supporting structures: https://www.rft.eu/en-gb/page/legal-context/european-regulations/standardised-constructions

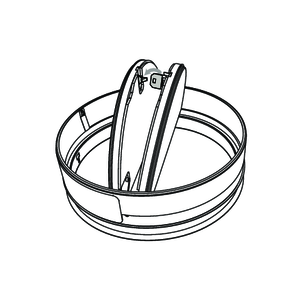

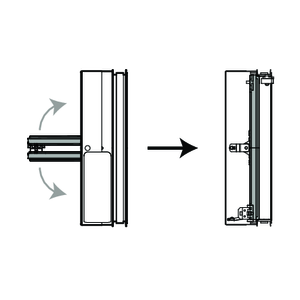

- Mounting direction: mounting possible with the axis in any position (0-360°)

- Direction of the airflow: discretionary

- If the product is manipulated in any other way than described in this manual, Rf-Technologies will decline any responsibility and the guarantee will expire!

Open to innovation, closed to fire

back

Open to innovation, closed to fire

back

.png)

.png)

.png)

.png)

.png)