- Home

- Products

- Fire damper cartridges

- SC-S

- Installation

SC-S - Installation

Installation in a fire resistant suspended ceiling

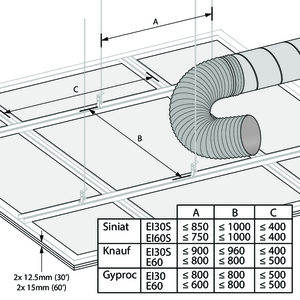

The product was tested and approved in:

- Metal studs gypsum plasterboard Type F (EN 520) 2 x 12.5 mm | EI 30 (ho o i) S - (300Pa) | Not applicable | Type of installation: built-in inside a duct, 0-360°; Fire side = side opposite to the fusible link | SC-S Ø 100-200 mm

- Metal studs gypsum plasterboard Type F (EN 520) 2 x 15 mm | EI 60 (ho o i) S - (300Pa) | Not applicable | Type of installation: built-in inside a duct, 0-360°; Fire side = side opposite to the fusible link | SC-S Ø 100-200 mm

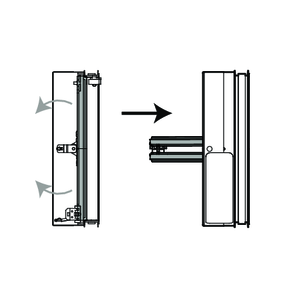

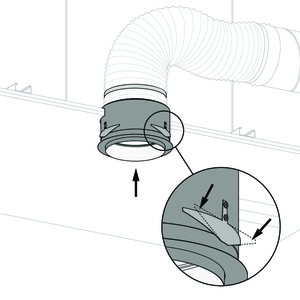

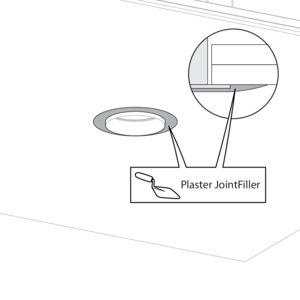

Build the fire resistant suspended ceiling according to the manufacturer's instructions. Provide a piece a flexible duct to connect the ventilation duct to the SC-S.

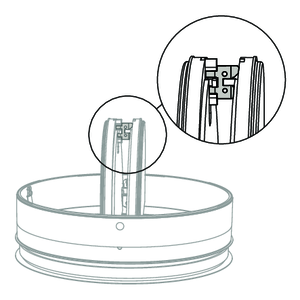

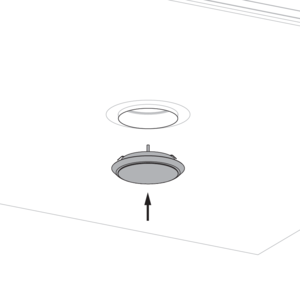

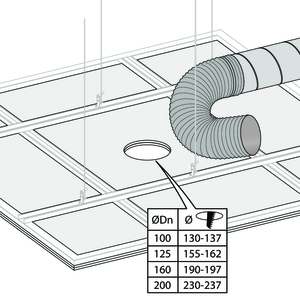

Make a round opening in the fire resistant suspended ceiling, with diameter as indicated in the table.

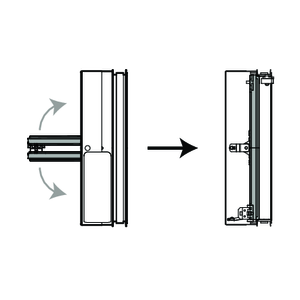

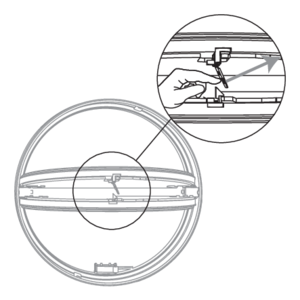

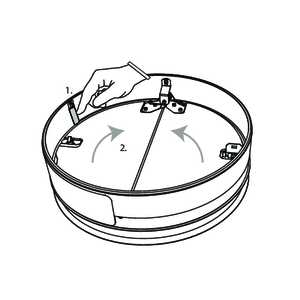

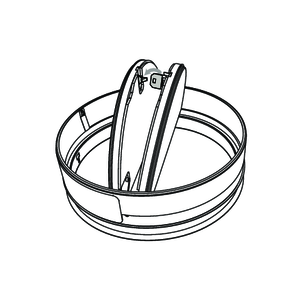

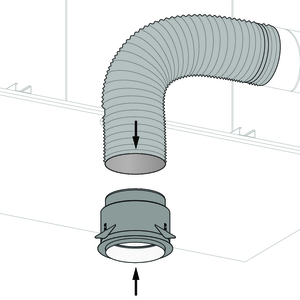

Arm the fire damper cartridge as explained in the operating instructions. Pull the flexible duct through the opening and place it over the connection provided for the ventilation duct. Attach the duct to the SC-S in an airtight manner.

Caution: Make sure the damper blades are in open position before installing into the ceiling.

Caution: Make sure the damper blades are in open position before installing into the ceiling.

General remarks

- Verify if the blade can move freely.

- The fire damper cartridge must remain accessible for inspection and maintenance.

- Please observe safety distances with respect to other construction elements.

Product-specific remarks

- The installation must comply with the installation manual.

- SC-S fire damper cartridges are tested in standardised fire resistant suspended ceilings in accordance with EN 1366-2 and EN 1364-2.

- Direction of the airflow: discretionary

- If the product is manipulated in any other way than described in this manual, Rf-Technologies will decline any responsibility and the guarantee will expire!

- Do not hold the SC-S by the finishing collar.

Open to innovation, closed to fire

back

Open to innovation, closed to fire

back