- Home

- Products

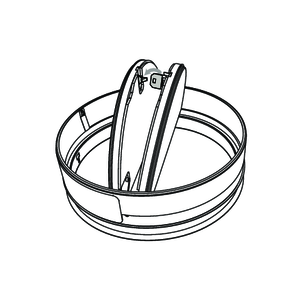

- Fire damper cartridges

- SC+60

- Installation

SC+60 - Installation

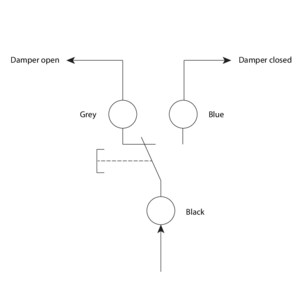

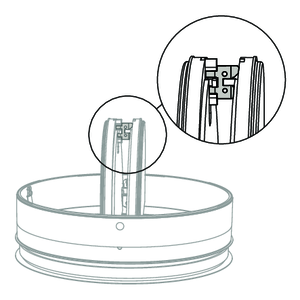

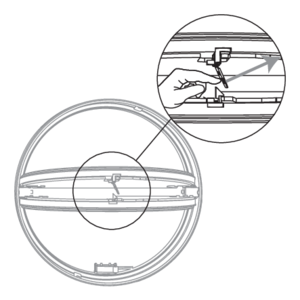

Electrical wiring

An end of range switch (FCU) can be mounted on the metal body. The purpose is to determine the position of the circular fire damper cartridge from a distance. 1mA...6A DC 5V....AC250V.

COM: black; NF: grey; NO: blue.

Power supply: Max 250V; Power consumption : Max 6A; Degree of protection: IP65; Length of cable: 500 mm.

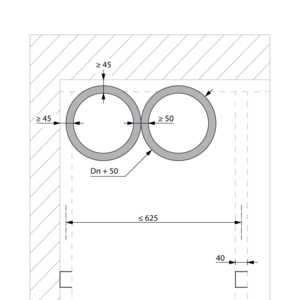

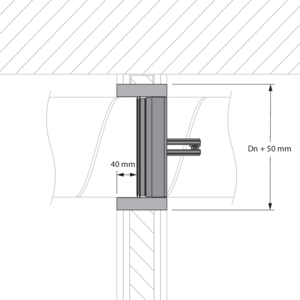

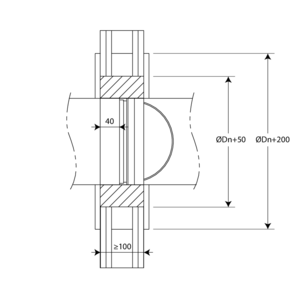

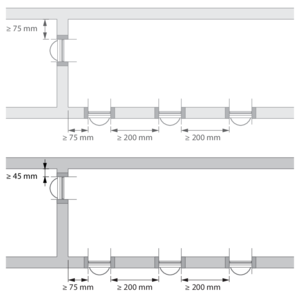

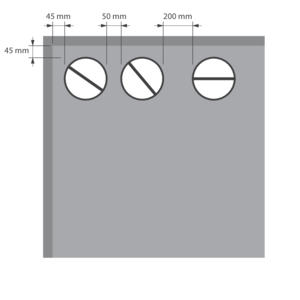

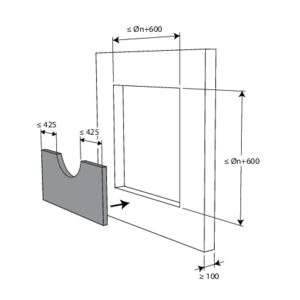

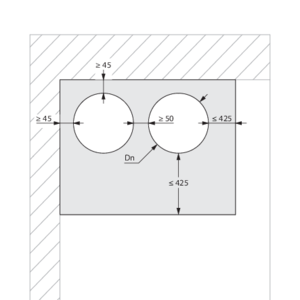

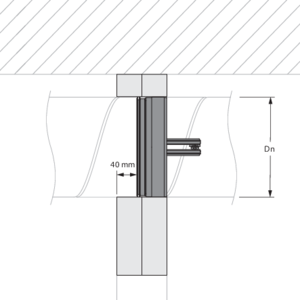

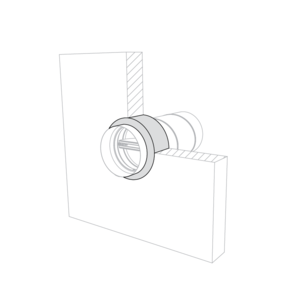

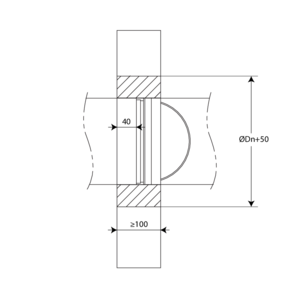

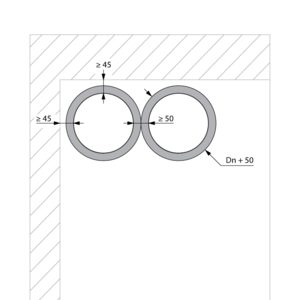

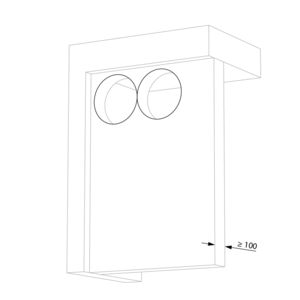

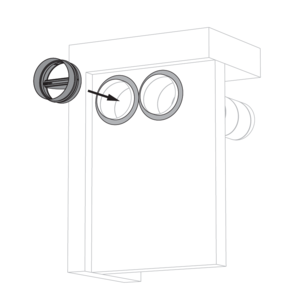

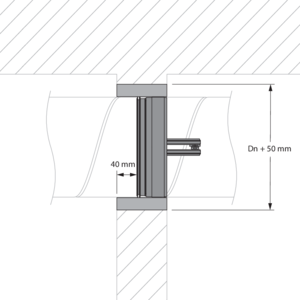

Installation at a minimal distance from another damper or from an adjacent supporting construction

According to the European test standard, a fire damper must be installed at a minimum distance of 75 mm from an adjacent wall and 200 mm from another damper, unless the solution was tested at a shorter distance.

This range of Rf-t fire dampers has been successfully tested and in several installation methods can be installed in a vertical supporting construction, at a distance below the minimum set by the standard - see below.

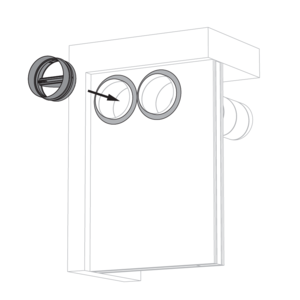

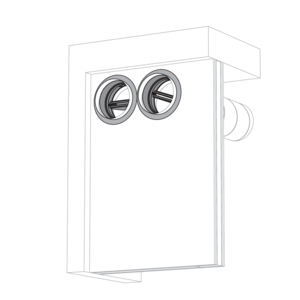

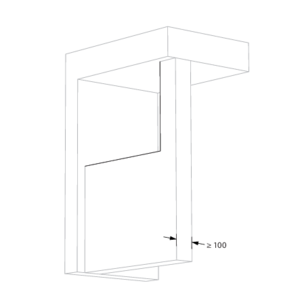

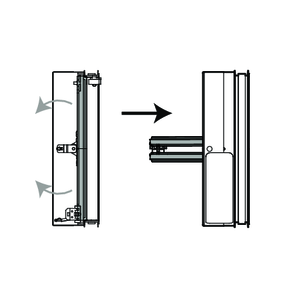

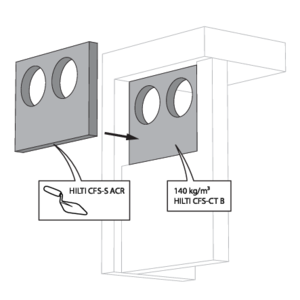

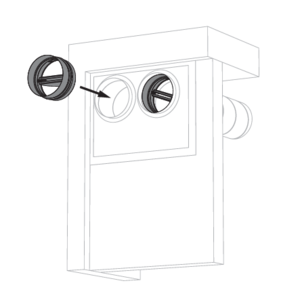

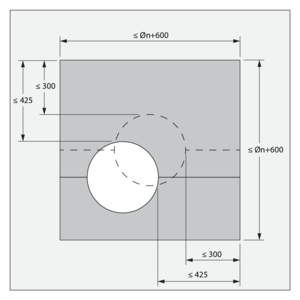

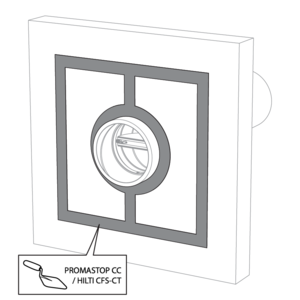

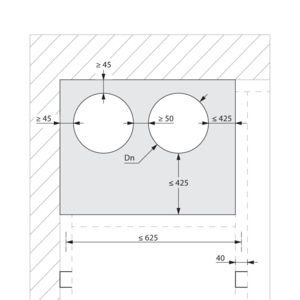

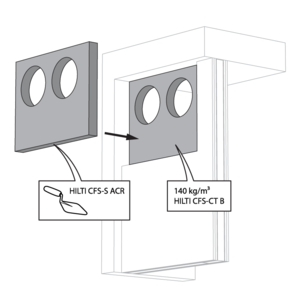

Installation in rigid wall, sealing with rigid stone wool boards with coating - SC+60

The product was tested and approved in:

- Aerated concrete ≥ 100 mm | EI 60 (ve i o) S - (300Pa) | Stone wool + coating ≥ 140 kg/m³ | Type of installation: built-in inside a duct, 0-360°. Minimal distances authorised. | SC+60 Ø 100-200 mm

The opening in the wall around the duct in which the fire damper cartridge is mounted, is sealed with 2 layers of 50 mm-thick stone wool panels with fire resistant coating on one side (type HILTI CFS-CT B).

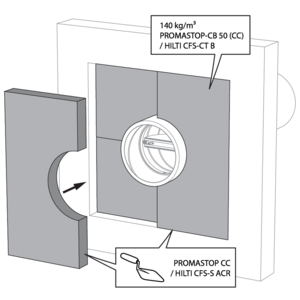

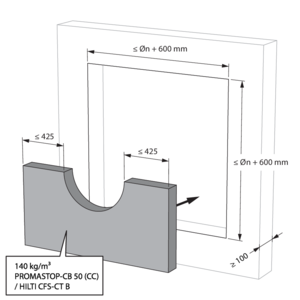

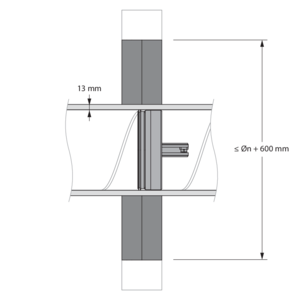

Installation in rigid wall, insulated duct, sealing with rigid stone wool boards with coating - SC+60

The product was tested and approved in:

- Aerated concrete ≥ 100 mm | EI 60 (ve i o) S - (300Pa) | Insulated duct (ArmaFlex EVO, ArmaFlex Protect – up to 13 mm) + stone wool + coating ≥ 140 kg/m³ | Type of installation: built-in inside a duct, 0-360° | SC+60 Ø 100-200 mm

The opening in the wall around the insulated duct, is sealed with 2 rigid stone wool boards of 50 mm with fire-resistant coating on one side (type Promastop CB50 / Hilti CFS-CT W).

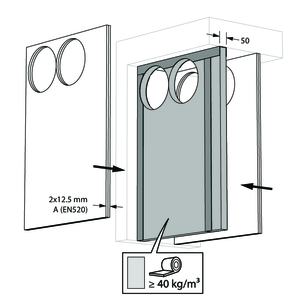

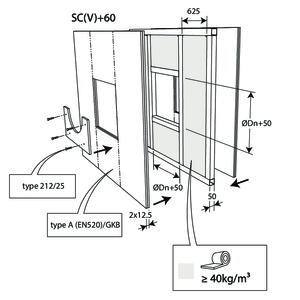

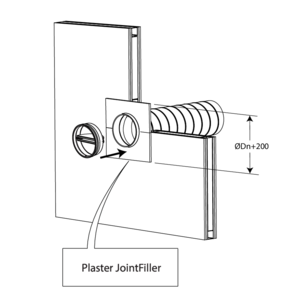

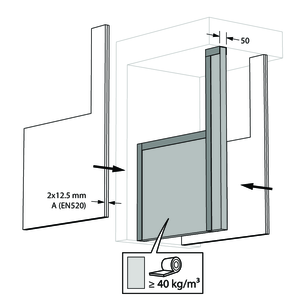

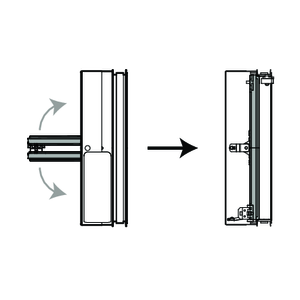

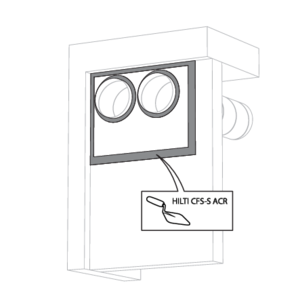

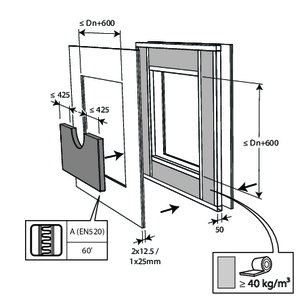

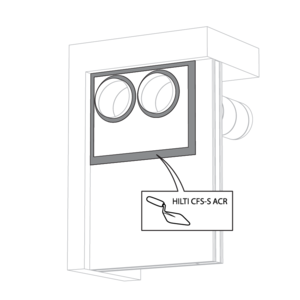

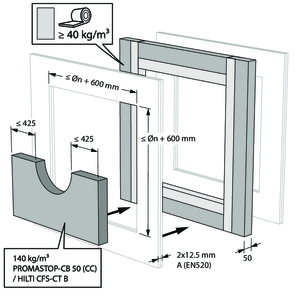

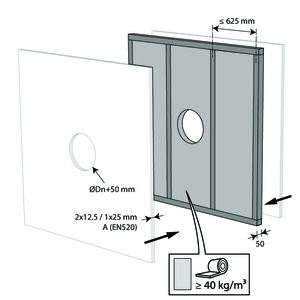

Installation in flexible wall, sealing with rigid stone wool boards with coating - SC+60

The product was tested and approved in:

- Metal studs gypsum plasterboard Type A (EN 520) ≥ 100 mm | EI 60 (ve i o) S - (300Pa) | Stone wool + coating ≥ 140 kg/m³ | Type of installation: built-in inside a duct, 0-360°. Minimal distances authorised. | SC+60 Ø 100-200 mm

The opening in the wall around the duct in which the fire damper cartridge is mounted, is sealed with 2 layers of 50 mm-thick stone wool panels with fire resistant coating on one side (type HILTI CFS-CT B).

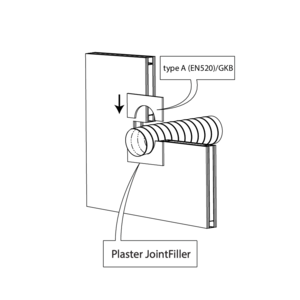

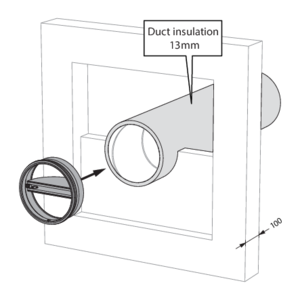

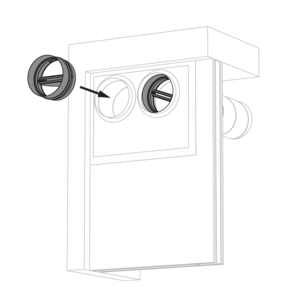

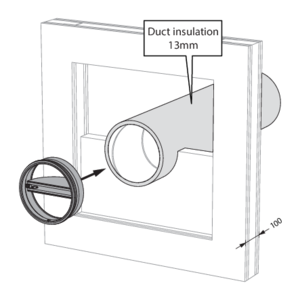

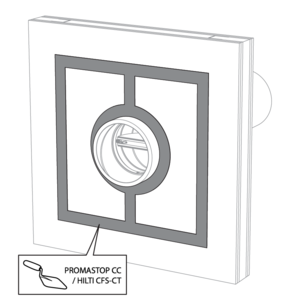

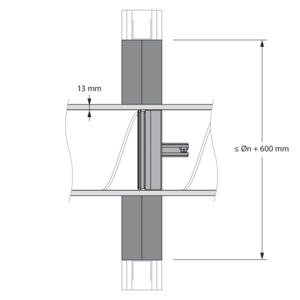

Installation in flexible wall, insulated duct, sealing with rigid stone wool boards with coating - SC+60

The product was tested and approved in:

- Metal studs gypsum plasterboard Type A (EN 520) ≥ 100 mm | EI 60 (ve i o) S - (300Pa) | Insulated duct (ArmaFlex EVO, ArmaFlex Protect – up to 13 mm) + stone wool + coating ≥ 140 kg/m³ | Type of installation: built-in inside a duct, 0-360° | SC+60 Ø 100-200 mm

The opening in the wall around the insulated duct, is sealed with 2 rigid stone wool boards of 50 mm with fire-resistant coating on one side (type Promastop CB50 / Hilti CFS-CT W).

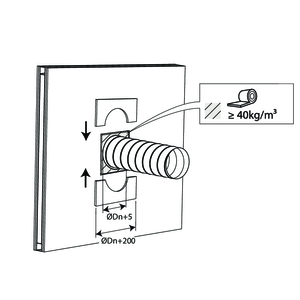

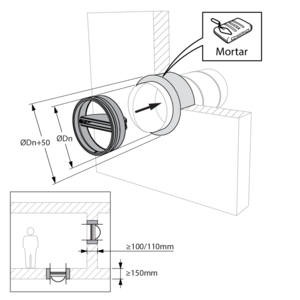

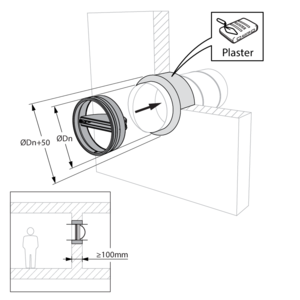

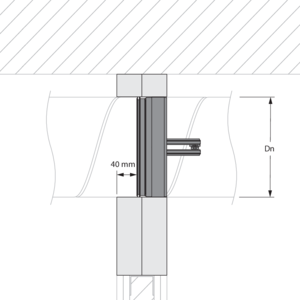

Installation in rigid wall and floor with mortar sealing - SC+60, SC+90 and SC+120

The product was tested and approved in:

- Aerated concrete ≥ 150 mm | EI 60 (ho i o) S - (300Pa) | Mortar | Type of installation: built-in inside a duct, 0-360° | SC+60 Ø 100-200 mm

- Aerated concrete ≥ 100 mm | EI 60 (ve i o) S - (300Pa) | Mortar | Type of installation: built-in inside a duct, 0-360° | SC+60 Ø 100-200 mm

General remarks

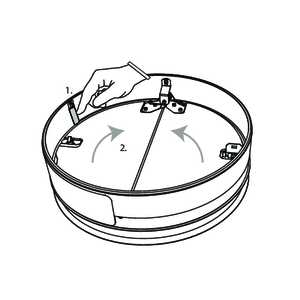

- Verify if the blade can move freely.

- The fire damper cartridge must remain accessible for inspection and maintenance.

- Please observe safety distances with respect to other construction elements.

Product-specific remarks

- The installation must comply with the installation manual and the classification report.

- The results obtained in standardised supporting structures according to EN 1366-2 also apply to similar supporting structures with a fire resistance, thickness and density equal to or greater than the supporting structure of the test. More information on standardised supporting structures: https://www.rft.eu/en-eu/page/fire-safety/legal-context/european-regulations/standardised-constructions

- Mounting direction: mounting possible with the axis in any position (0-360°)

- Direction of the airflow: discretionary

- If the product is manipulated in any other way than described in this manual, Rf-Technologies will decline any responsibility and the guarantee will expire!

Open to innovation, closed to fire

back

Open to innovation, closed to fire

back

_INST_FW_GIPS_2.png)

_INST_FW_GIPS_3.png)