- Home

- Products

- Fire dampers

- CRS60

- Installation

CRS60 - Installation

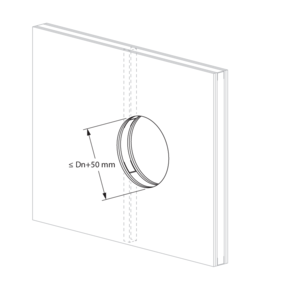

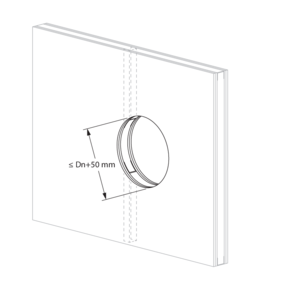

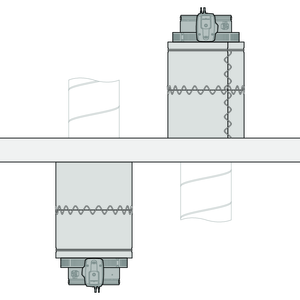

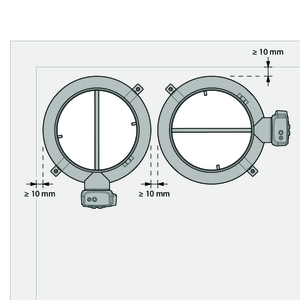

Installation at a minimal distance from another damper or from an adjacent supporting construction

Principle

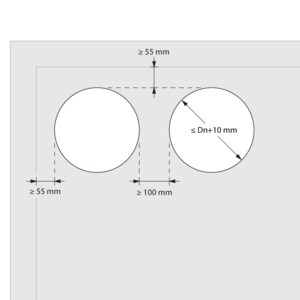

According to the European test standard, a fire damper must be installed at a minimum distance of 75 mm from an adjacent wall and 200 mm from another damper, unless the solution was tested at a shorter distance.

This Rf-Technologies fire damper has been successfully tested and may be installed at a shorter distance than the minimum specified by the standard in the following installation situations: • Installation in rigid wall, sealing with acrylic sealant • Installation in flexible wall (metal stud gypsum plasterboard wall), sealing with acrylic sealant • Installation in rigid floor, sealing with acrylic sealant

According to the European test standard, a fire damper must be installed at a minimum distance of 75 mm from an adjacent wall and 200 mm from another damper, unless the solution was tested at a shorter distance.

This Rf-Technologies fire damper has been successfully tested and may be installed at a shorter distance than the minimum specified by the standard in the following installation situations: • Installation in rigid wall, sealing with acrylic sealant • Installation in flexible wall (metal stud gypsum plasterboard wall), sealing with acrylic sealant • Installation in rigid floor, sealing with acrylic sealant

Restrictions

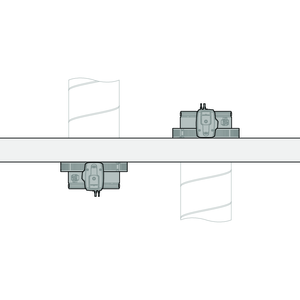

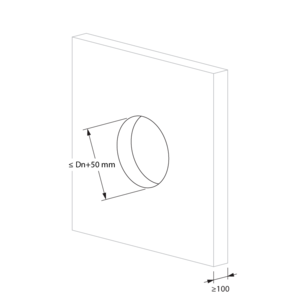

A maximum of 2 dampers may be installed next to each other at a minimum distance from wall and/or ceiling/floor.

For installation of a third fire damper (or a second pair of fire dampers), a distance of 200 mm should be respected from the first pair (to be measured from damper tunnel to damper tunnel).

A maximum of 2 dampers may be installed next to each other at a minimum distance from wall and/or ceiling/floor.

For installation of a third fire damper (or a second pair of fire dampers), a distance of 200 mm should be respected from the first pair (to be measured from damper tunnel to damper tunnel).

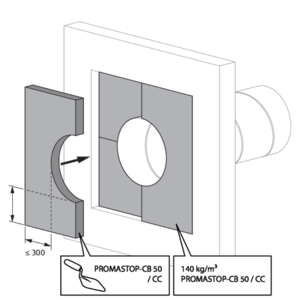

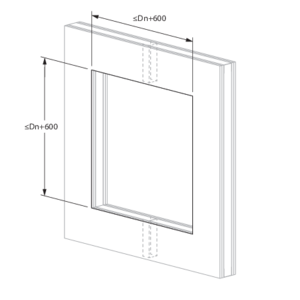

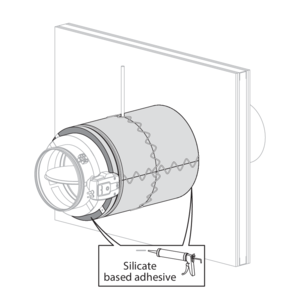

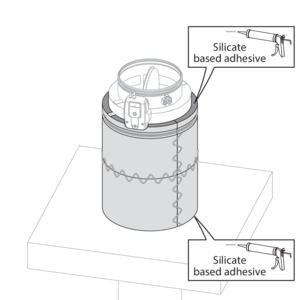

Installation in rigid wall, sealing with rigid stone wool boards with coating

The product was tested and approved in:

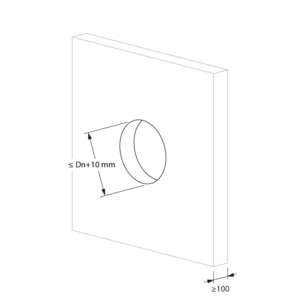

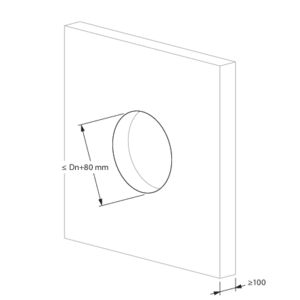

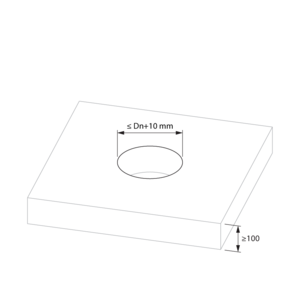

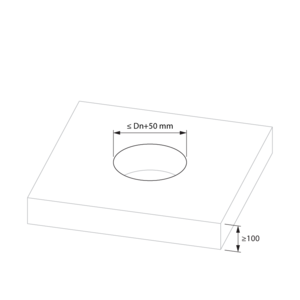

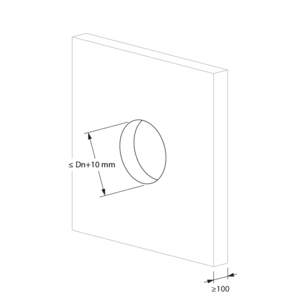

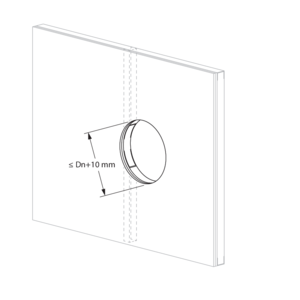

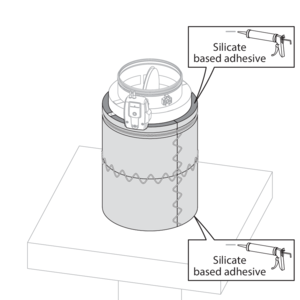

- Aerated concrete ≥ 100 mm | EI 60 (ve i o) S - (300 Pa) | Stone wool + coating ≥ 140 kg/m³ | Type of installation: surface-mounted, 0-360° (300 Pa) | Ø 100-630 mm

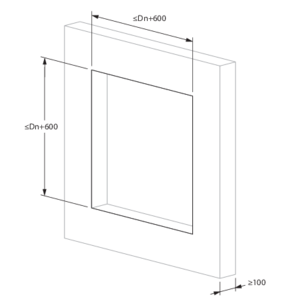

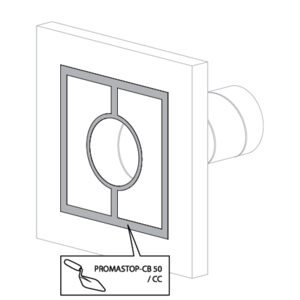

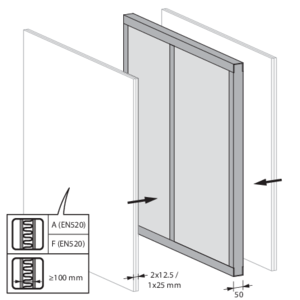

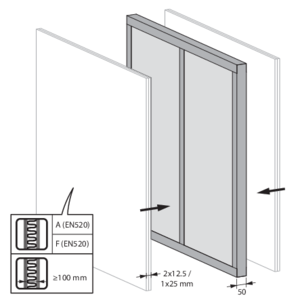

Installation in flexible wall, sealing with rigid stone wool boards with coating

The product was tested and approved in:

- Metal studs gypsum plasterboard Type A (EN 520) ≥ 100 mm | EI 60 (ve i o) S - (300 Pa) | Stone wool + coating ≥ 140 kg/m³ | Type of installation: surface-mounted, 0-360° (300 Pa) | Ø 100-630 mm

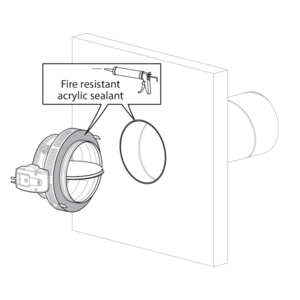

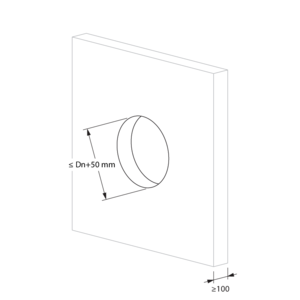

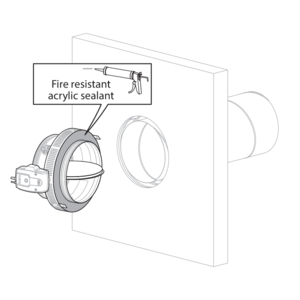

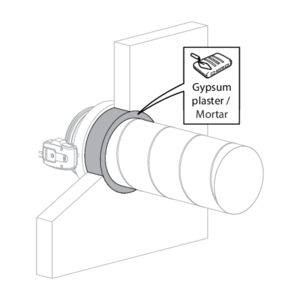

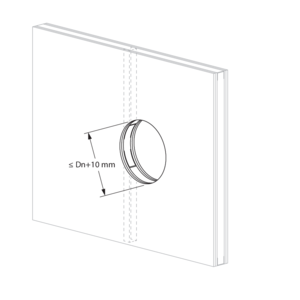

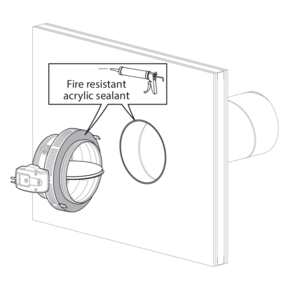

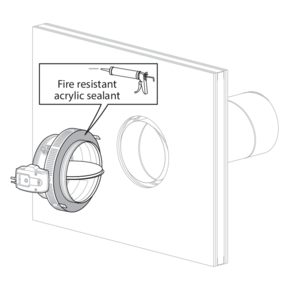

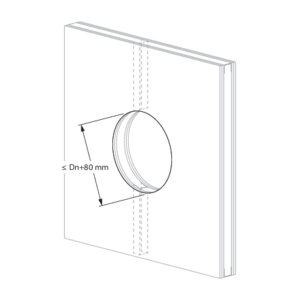

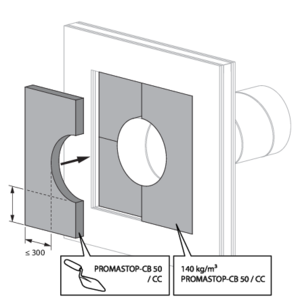

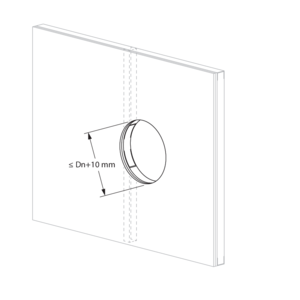

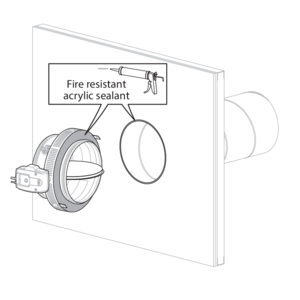

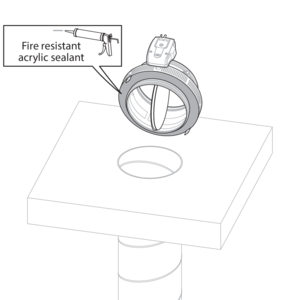

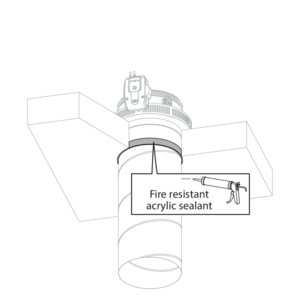

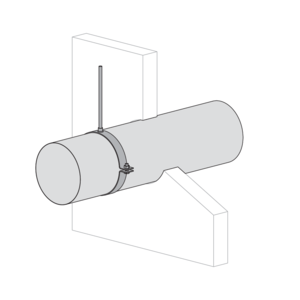

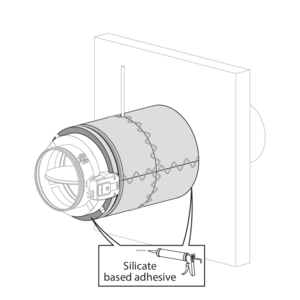

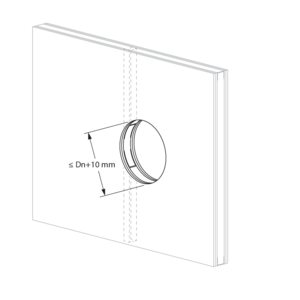

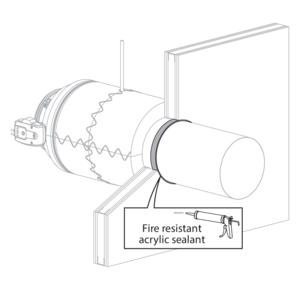

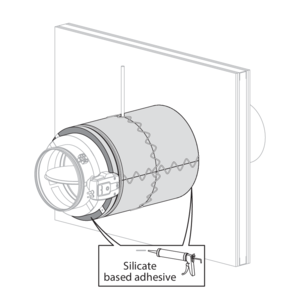

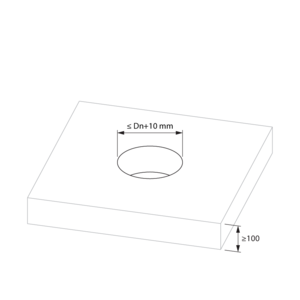

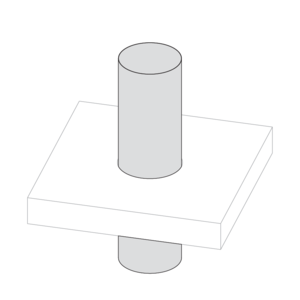

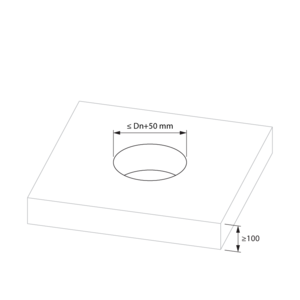

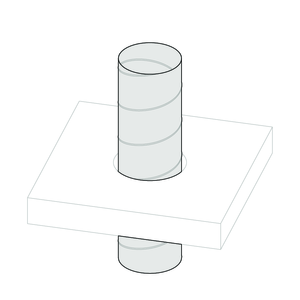

Installation remote from a rigid wall, sealing with acrylic sealant

The product was tested and approved in:

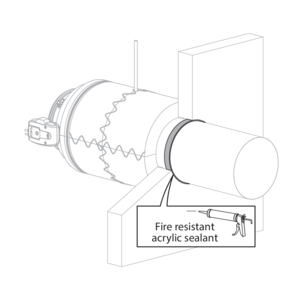

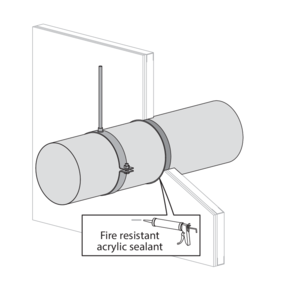

- Aerated concrete ≥ 100 mm | EI 60 (ve i o) S - (300 Pa) | Fire resistant acrylic sealant | Type of installation: remote from the wall, 0-360° | Ø 100-630 mm

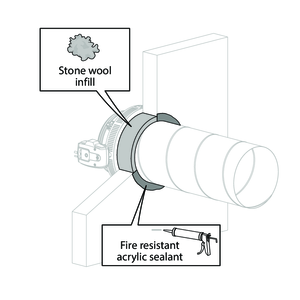

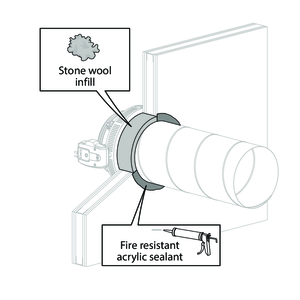

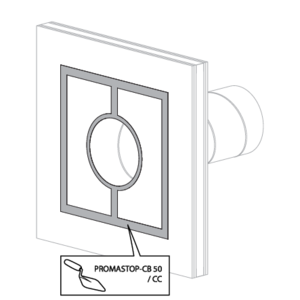

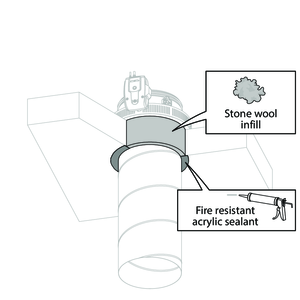

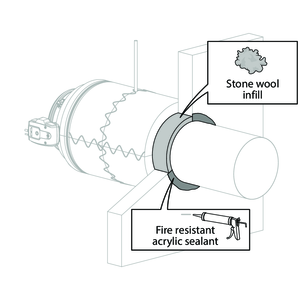

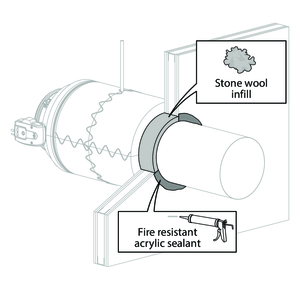

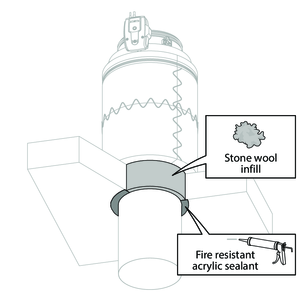

Installation remote from a rigid wall, sealing with stone wool

The product was tested and approved in:

- Aerated concrete ≥ 100 mm | EI 60 (ve i o) S - (300 Pa) | Stone wool + coating with acrylic sealant | Type of installation: remote from the wall, 0-360° | Ø 100-630 mm

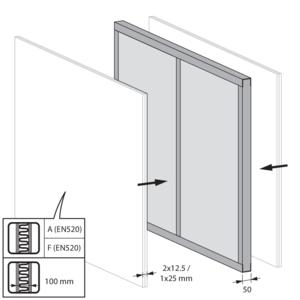

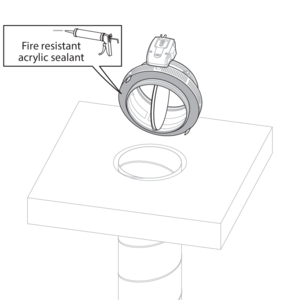

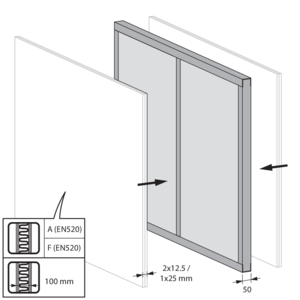

Installation remote from a flexible wall, sealing with acrylic sealant

The product was tested and approved in:

- Metal studs gypsum plasterboard Type A (EN 520) ≥ 100 mm | EI 60 (ve i o) S - (300 Pa) | Fire resistant acrylic sealant | Type of installation: remote from the wall, 0-360° | Ø 100-630 mm

Installation remote from a flexible wall, sealing with stone wool

The product was tested and approved in:

- Metal studs gypsum plasterboard Type A (EN 520) ≥ 100 mm | EI 60 (ve i o) S - (300 Pa) | Stone wool + coating with acrylic sealant | Type of installation: remote from the wall, 0-360° | Ø 100-630 mm

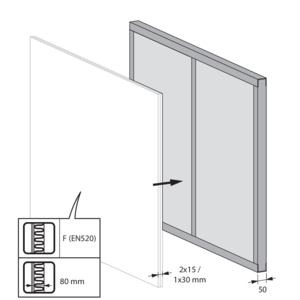

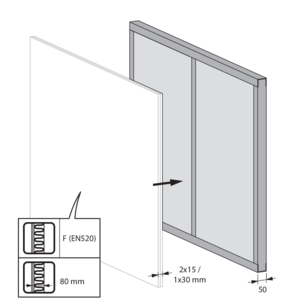

Installation remote from a shaftwall

The product was tested and approved in:

- Metal studs gypsum plasterboard Type F (EN 520) ≥ 80 mm | EI 60 (ve i o) S - (300 Pa) | Fire resistant acrylic sealant | Type of installation: remote from the wall, 0-360° | Ø 100-630 mm

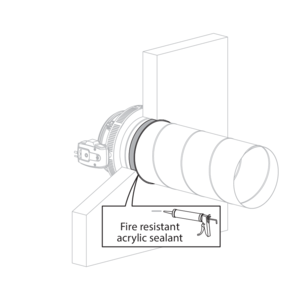

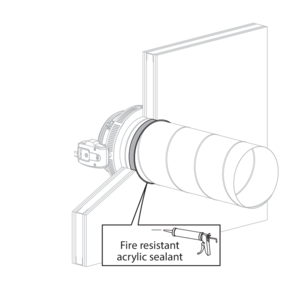

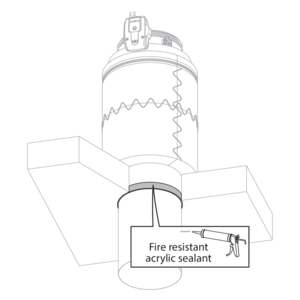

Installation remote from a floor, sealing with acrylic sealant

The product was tested and approved in:

- Aerated concrete ≥ 100 mm | EI 60 (ho i o) S - (300 Pa) | Fire resistant acrylic sealant | Type of installation: remote from the wall, 0-360° | Ø 100-630 mm

Installation remote from a floor, sealing with stone wool

The product was tested and approved in:

- Aerated concrete ≥ 100 mm | EI 60 (ho i o) S - (300 Pa) | Stone wool + coating with acrylic sealant | Type of installation: remote from the wall, 0-360° | Ø 100-630 mm

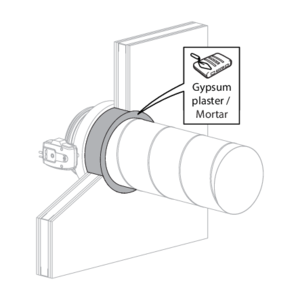

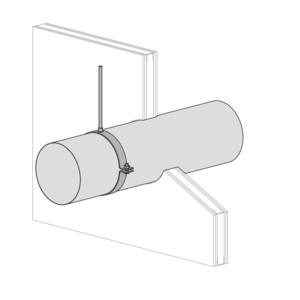

General remarks

- The installation must comply with the installation manual and the classification report.

- Axis orientation: see the declaration of performance.

- Avoid obstruction of adjoining ducts.

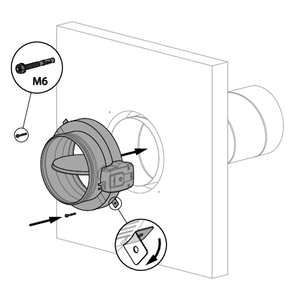

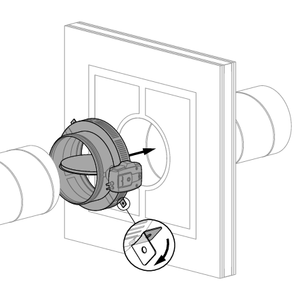

- Product installation: always with closed damper blade.

- Verify if the blade can move freely.

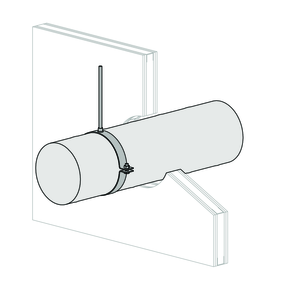

- Please observe safety distances with respect to other construction elements. The operating mechanism must also remain accessible: allow for a clearance of 200 mm around the housing.

- The air tightness class will be maintained if the damper is installed according to the installation manual.

- Rf-t fire dampers are always tested in standardised constructions according to EN 1366-2. The achieved results are valid for similar supporting constructions with a fire resistance, thickness and density equal or superior to the supporting construction used during the test.

- If the wall thickness exceeds the minimum thickness specified in our installation instructions, the following conditions apply to the sealing depth: - For flexible walls and sandwich panel system walls, the seal must always be applied over the full depth of the wall. - With rigid walls, rigid floors and plaster block walls, the minimum sealing depth as indicated in our installation instructions (often equal to the minimum wall thickness) is sufficient. Apply the seal at the height of the damper blade (from the wall limit indication).

- When installing a fire damper in a flexible metal stud wall, some installation methods do not require reinforcing profiles around the wall opening from a fire protection point of view (see below). Always follow the general instructions of the manufacturer of these wall systems when building this type of wall.

- The damper must remain accessible for inspection and maintenance.

- Schedule at least 2 visual checks each year.

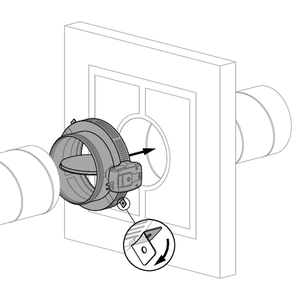

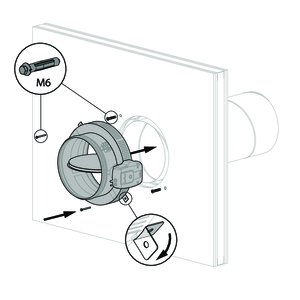

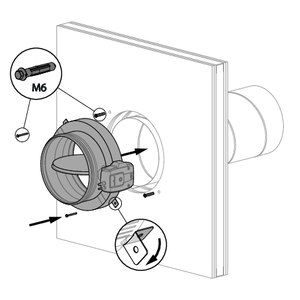

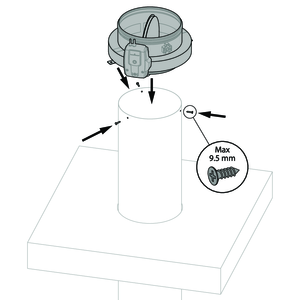

Product-specific remarks

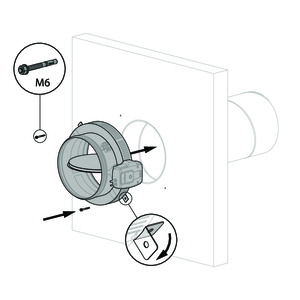

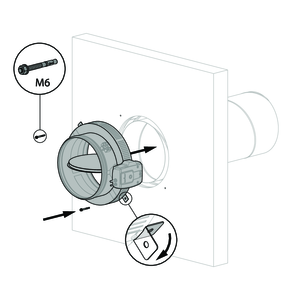

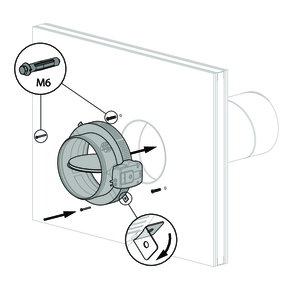

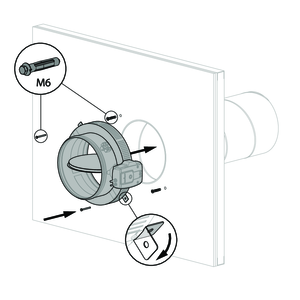

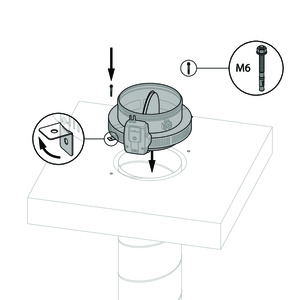

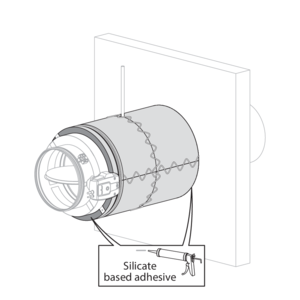

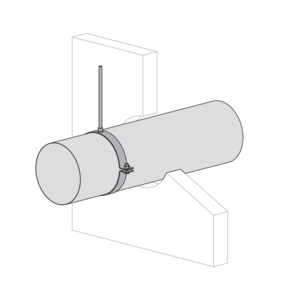

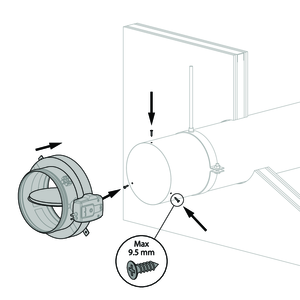

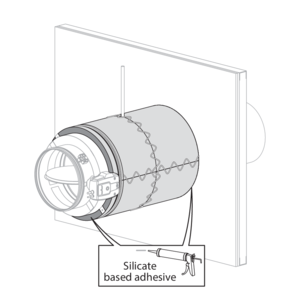

- On one side of the fire damper, the surface-mounted collar acts as a stop for the air duct. On the other side, the stop for the duct is formed by the ends of the fixing plates and the mechanism bridge.

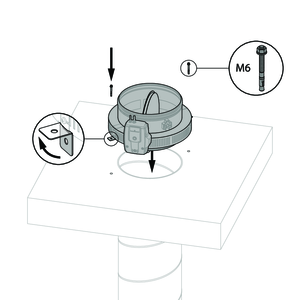

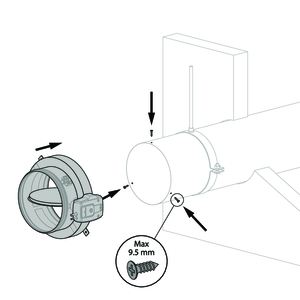

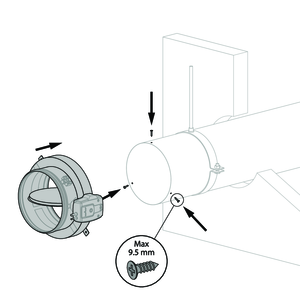

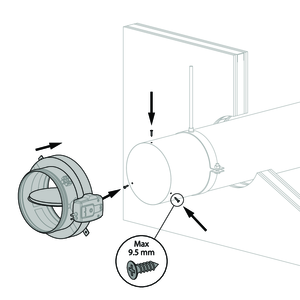

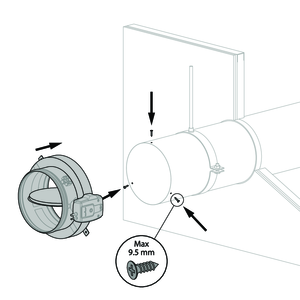

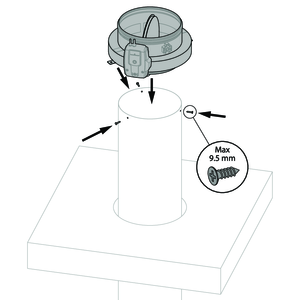

- It is not required to fix the duct to the fire damper with screws, but it is allowed. The screws may be inserted through the rubber sealing ring. Maximum screw length 9.5mm.

- Diameter 100 to 315 has 2 fixation plates. Diameter 400 to 630 has 4 fixation plates.

Open to innovation, closed to fire

back

Open to innovation, closed to fire

back